Latest topics from our company

Customer application report: Process engineer at Geberit in Pfullendorf on Lake Constance

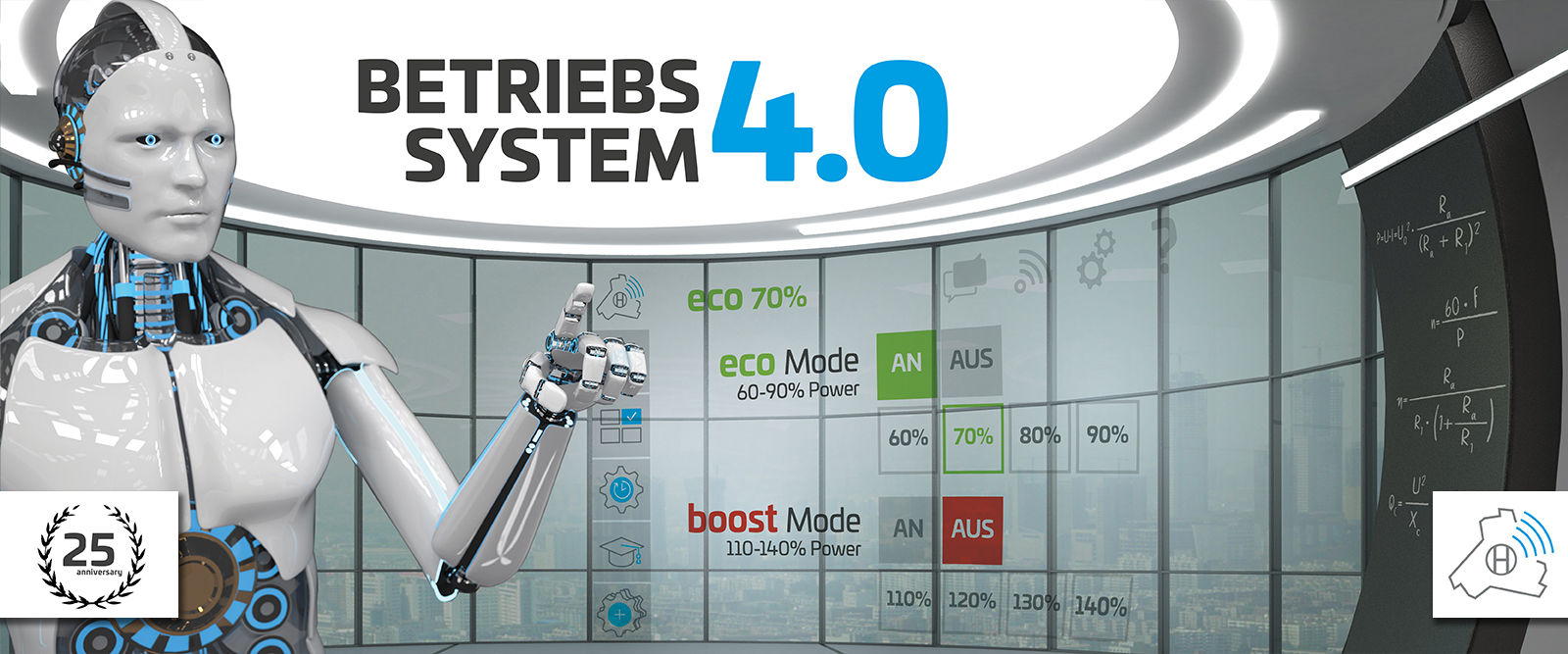

Save up to 50 % energy in the production of ground material

Digitally Controlled Grinders

At Fakuma, Hellweg Maschinenbau will be presenting a selection of its pioneering, digitally...

New Wet Grinder Minimizes Operating Costs

Hellweg Maschinenbau, a manufacturer of advanced, digitally controlled shredders for efficient...

Hellweg granulators

for processing valuable plastics waste

Effective plastic recycling with granulation machines from Hellweg Maschinenbau

As a family-owned company, Hellweg Maschinenbau GmbH & Co. KG is managed by the second generation of the founding Hellweg family and specialises in production and worldwide sale of high-grade granulation machines.

The product programme involves granulators that work according to a scissor and slanted cutting principle and that are constructed as laboratory granulators, machine-side granulators, toothed roll granulators, central granulators, lump granulators, punched skeleton granulators and film & edge strip granulators.

Hellweg scissor-cut rotors are produced by milling from a single metal preform, so they do not have any welding seams or imbalance, while featuring high stability at highest possible torque. This elaborate production method results in self-dosing behaviour of the granulators, as well as enabling all engineering plastics to be thoroughly granulated. It does not matter here whether the material has hard, fragile, tough or even soft properties. Hellweg granulators based on the scissor and slanted cut working principle have been proven to be successfully used for granulation of the following plastics:

ABS, ASA, EPS, EPDM, EPS, EVA, CFK, GF, PA, PA6, PA66GF, PC, PE, PE-HD, PE-LD, PP, PET, PPS, PS, PS-E, PTFE, POM, PVB, PVC, PU, PUR, PBT, PEEK, PMMA, TPE

Guaranteed process security during and after granulation

Hellweg Maschinenbau additionally offers solutions and customer-tailored tasks for customers in the plastics and recycling industries, as well as for the food and paper industries. Aside from the focus on granulation machinery for plastics, Hellweg offers numerous customer-oriented special solutions addressing subjects of edge-strip disposal, processing and recycling.

Hellweg film cutters guarantee a clean, sharp edge cut when opening up blown film bubbles into flat film, or in confection of film webs into packaging.

Hellweg pipe cutters are integrated within extraction piping and serve here to reduce volume, as well as smooth conveying away edge-strip material from thin film production locations.

Hellweg guillotines are used to pre-shred edge-strips in sheet production and can break up sheets in thickness up to 18 mm via an eccentric movement solution that remains stabile over a long period.

However, when equipped with roll-fed intake equipment for thin film edge-strips, Hellweg granulators can process edge-strips into either flakes or granule form, as material that can be directly re-introduced into subsequent processes.

Our quality guarantee

Hellweg Maschinenbau produces its machines entirely itself and can therefore guarantee constant quality. The quality assurance system, which we developed ourselves, monitors the entire production chain. All products are submitted to extensive testing prior to despatch.

With their solid construction, Hellweg granulators stand for advanced technology and guarantee compliance with the highest demands for quality – with a well balanced price-performance relationship.